The LED and Halogen process.

It would be remiss of me not to mention the difference between how LEDs and Halogen bulbs work at the outset, since many advantages and disadvantages of each lighting system, is tied directly to how they work. In fact while this post ultimately compares CG Automotive's LED bulb kit, with my OEM Halogen bulbs, you will find that the difference in processes and the choices made for the particular Bulb kit, imposed by the processes, drives the comparison. Lets dive in. Regarding the LEDs process, I can do no better than Phillips' explanation that:

as indicated by its name, [light-emitting diode], the LED is a diode that emits light. A diode is a device that allows current to flow in only one direction. Almost any two conductive materials will form a diode when placed in contact with each other. When electricity is passed through the diode the atoms in one material (within the semiconductor chip) are excited to a higher energy level. The atoms in that first material have too much energy and need to release that energy. The energy is then released as the atoms shed electrons to the other material within the chip. During this energy release light is created. The color of the light from the LED is a function of the ingredients (materials) and recipes (processes) that make up the chip.

Compare this to a Halogen bulb's incandescence process. A Halogen bulb consists of: a glass enclosure highly resistant to heat, gas (typically argon and nitrogen), and a tungsten filament. If you've ever picked up a bulb and seen the suspended metal piece inside, you've seen the filament; it typically shakes or vibrates if you move the bulb with enough vigor. The Tungsten filament in your Halogen bulb receives electricity from your car’s battery and heats up to well over 2,000 degrees Celsius. At that point the filament glows brightly, creating enough light to illuminate your path.

The difference between the processes results in some key advantages for LED lighting systems. For example, LEDs have high-levels of brightness and intensity, with a very low energy draw and relatively low heat radiation, making LEDs reliable and long lasting.

Additionally, similar to a solid state disk (SSD) in a computer, an SSL or solid state luminaire is highly resistant to shock and vibration; there is no suspended tungsten filament to bounce around when you hit that nasty "Land-of-the-Lost" pothole. Still, my favorite trait of an LED has to be that you can actually touch the bulb during installation without reducing its life span. Where LEDs are resistant to substances such as finger grease (and we all have it), our human slime is highly problematic for Halogen bulbs. This is because certain substances on the Halogen bulb's glass enclosure, like finger grease, will cause it to heat unevenly and burnout prematurely. As such, the bulb in a Halogen lighting system, typically sits amongst the components with the highest failure rate in a that type of lighting system. In contrast, the SSL Luminaire - Failure by Category chart above shows that the opposite is true in an LED lighting system, where the LED package or 'bulb', sits amongst the components with the lowest failure rate, at seven percent.

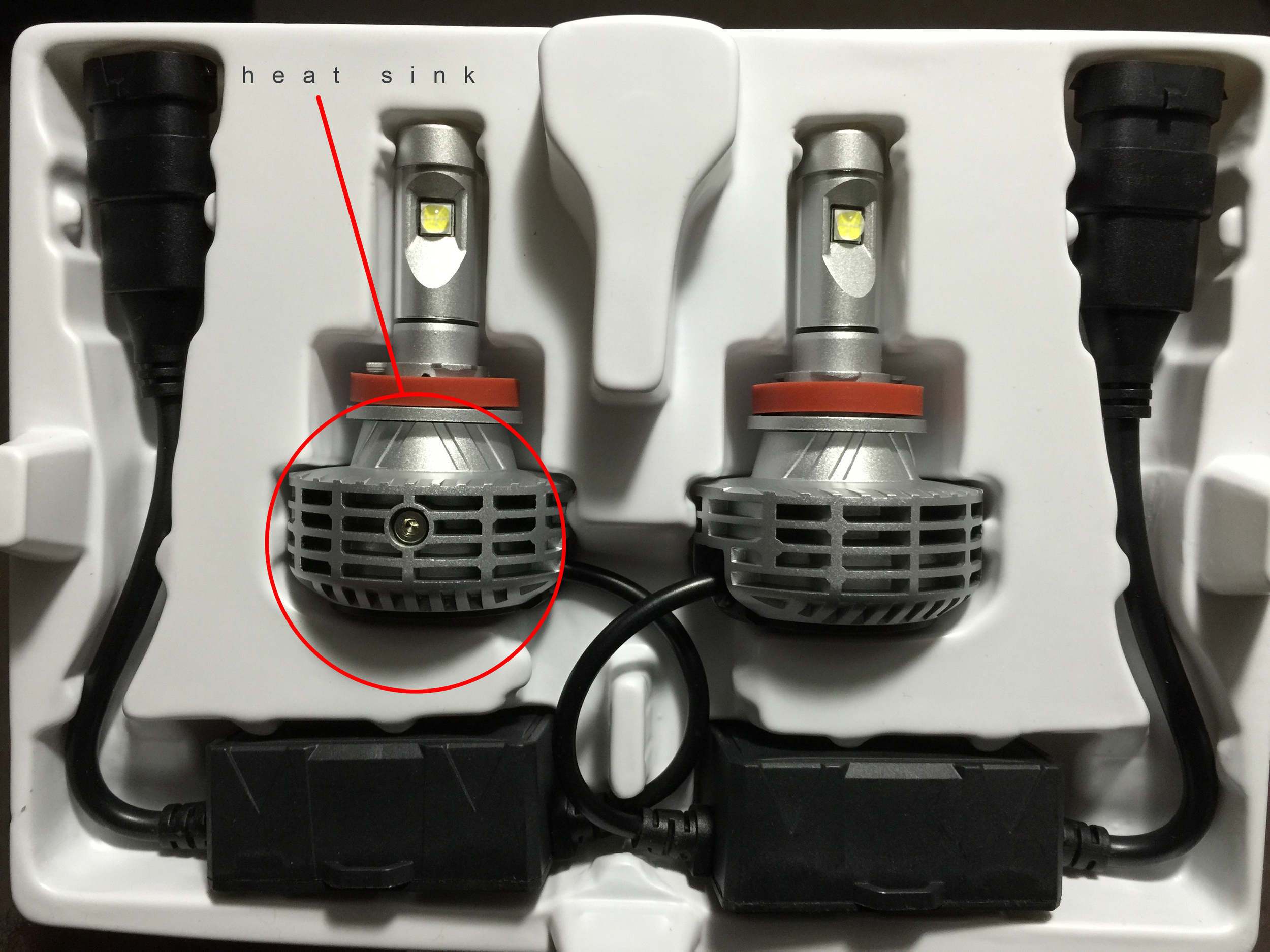

Another interesting difference between the LED and Halogen process, lies in heat management for LED bulbs expected to shine brightly for extended periods of time. Note the SSL Reliability Management chart below for a general understanding of an LED lighting system.

You will quickly notice that Thermal Management (colored red on the chart) is an important and substantial part of an LED luminaire. Perhaps this will not come as a surprise in light of the generally accepted Arrhenius or “10-degree" rule for electronic components, which posits:

Every 10 degrees (Celsius) of operating temperature reduction, effectively doubles the life of an electronic component.

A significant consideration in choosing CG Automotive's LED bulb kit was the fact that there was proper thermal management with no moving parts. Heatsinks are used for heat dissipation instead of a fans to cool the package; no moving parts and less heat means longer lasting LEDs. At this point you may be wondering why it is necessary to have heatsinks or fans in the first place, especially considering that I just mentioned the relatively low heat radiation of LEDs moments ago. Further, your Halogen bulbs had no visible heat sink, or fan, and they were fine; right? Well the Next Generation Lighting Industry Alliance and LED Systems Reliability Consortium explains the need for thermal management this way in their 2014 white paper :

LEDs convert electricity to light directly within the device. They do not radiate heat but rather retain it so dissipation must be by convection or conduction. This generally results in higher local temperatures within the luminaire, the extent depending on design, which will accelerate changes within the LED and in nearby electronic components.

It is important to keep in mind that LEDs, with a typical lifespan of at least 25,000 hours, can last much longer that Halogen bulbs, which have an average lifespan of 1,000 hours. In other words, proper heat dissipation enables an even longer life-span for LEDs. In addition to the heat dissipation mechanism and durability of an LED system, other desirable traits of CG Automotive's LED Bulb Kit included the use of Phillips LEDs for long range lighting, the price ($111.38 with shipping), and importantly, the ease of installation.

The LED bulb kit is plug and play.

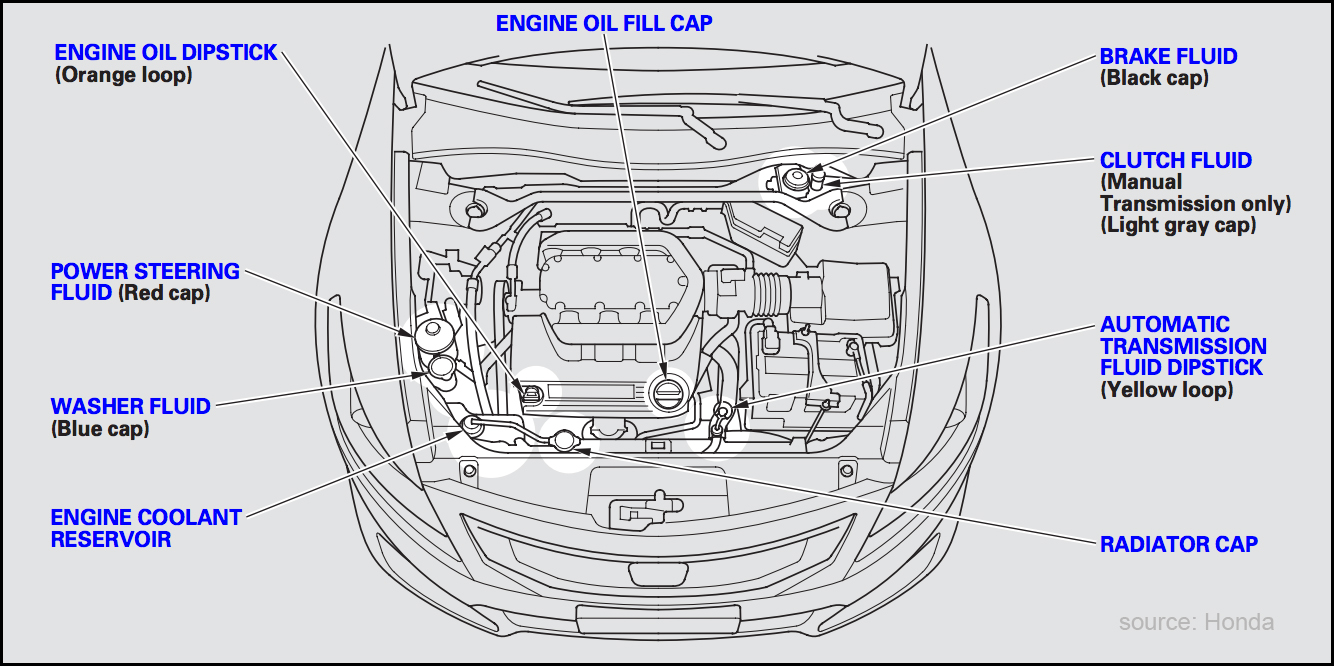

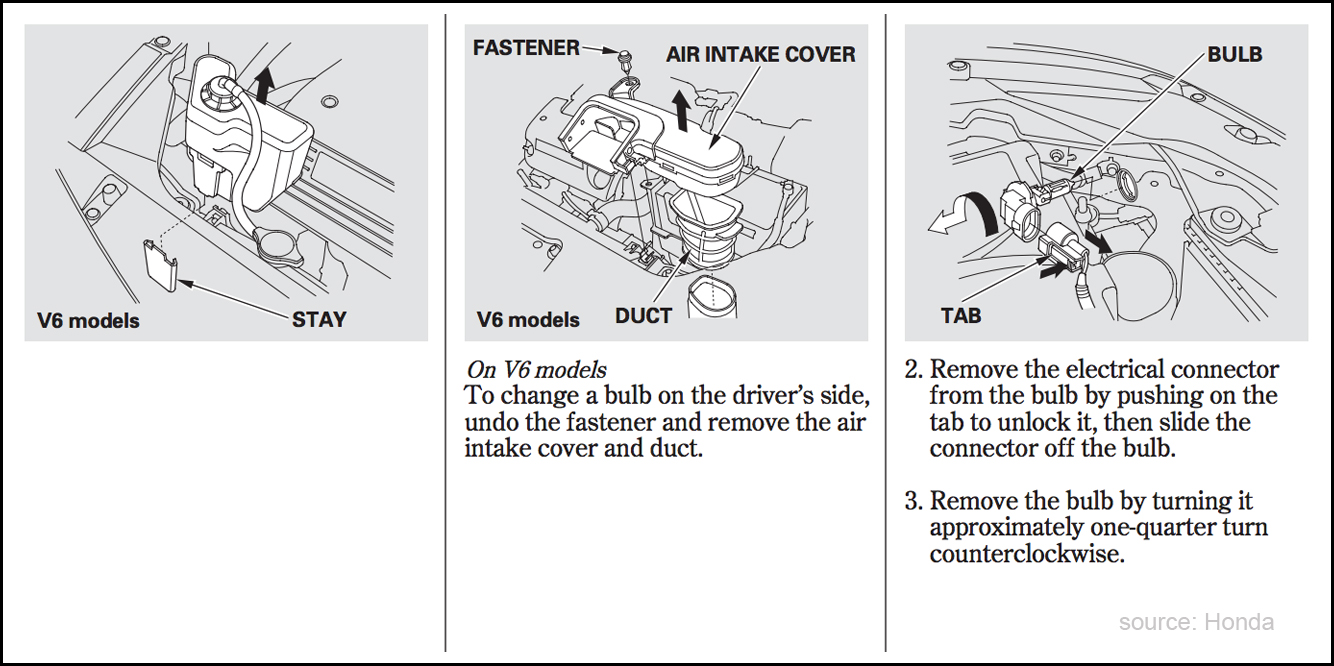

Installation, of each LED bulb was fairly easy. They literally just plug in to the factory wire harness. However, you will likely spend a few minutes of the installation trying to find a place to tuck the ballast. Conveniently, there was just enough length provided in the attached connector cord to enable connection of the LEDs to my Accord's headlamp wire harness, and to facilitate placing the ballast off to the side and out of the way. In fact, challenges during installation is much more likely to arise out of the design of your vehicle than connecting and locking the LEDs into your headlamp. That is, it seems to be increasingly difficult to replace anything in a modern car, including a simple headlamp bulb. For example, you may need to remove several pieces of useless aesthetic plastic or maybe even some functional components from your vehicle before you will have enough room to change your headlamp bulb. Replacing the passenger side headlamp bulb was easy enough in my 2010 Honda Accord without removing any parts. Honda recommends removing the engine coolant reservoir to get to the passenger side bulb; I found this to be unnecessary, but doing so may save you a few scrapes. The driver side bulb replacement was more problematic. You simply must remove some component from your vehicle to reach the bulb. As you can see from the diagram below, its pretty tightly packed under the hood. You can find Honda's recommended methodology for replacement below, and you can find the entire Accord user manual here for more information. Of note, you may gain the room you need to replace the bulb, should you get rid of that factory air box, and install a cold air intake; only a suggestion.

The LEDs work and look great.

I have been using CG Automotive's LED bulb kit for a little under a month. They work great. The LEDs are bright and do not look like imitation HIDs, or cheap Halogen blue lens bulbs. They instantly made my Accord headlamps look more modern with a soft pure white appearance, as opposed to the stock yellowish hue, the hallmark of Halogen. Relatedly, the LEDs tend to more closely recreate daylight where, the Halogen bulbs seem to to hack the night, just enough to enable us to traverse pitch-black parkways from point A to point B.

You can get an idea of just how bright the LED headlamps are without unwanted dispersion, from the accompanying image of the front of my Accord. I have heard and read about issues for oncoming traffic caused by the brightness of LEDs. Thus far, I have not received any adverse reaction to driving with LEDs; no high-beams, no honk and accompanying dirty look, no 'bird' as another motorist zooms by, nothing.

Before making the leap to LEDs I thought about changing my Halogen bulbs for some time. I briefly considered HIDs, but remembered having problems after replacing the OEM HIDs in my G35 with aftermarket HIDs; the bulbs tended to flicker if the car received a significant jolt. Having finally made the leap to LEDs I wonder why I waited so long. It was the right choice for me; none of the aforementioned issues are present. On the contrary, the LEDs have been rock solid and functional. If you've been considering the same move, jump in.